Plastic cutting boards are cheap, lightweight, and easy to clean—but studies show they can release microplastics into food with every cut. USDA and FDA say they’re safe if properly maintained, yet the risks are more complicated. Here’s a clear look at their pros, cons, and safer alternatives like wood, bamboo, or titanium.

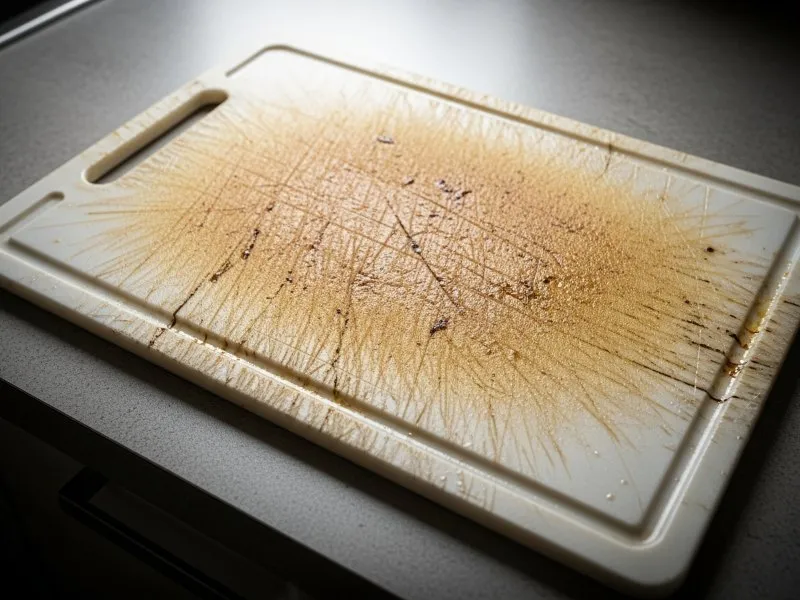

- A plastic cutting board in daily use—lightweight and convenient, but not without hidden risks

The Truth About Plastic Cutting Board Safety

Are plastic cutting boards safe? Yes — if you use them correctly with proper sanitization, regular cleaning, and timely replacement when damaged.

However, the complete picture isn’t quite so simple. When not properly maintained, plastic cutting boards can become breeding grounds for bacteria and sources of microplastic contamination in your food.

- Overused plastic cutting board with deep grooves and warping—prime spots for bacteria to hide

Recent scientific findings add new considerations to plastic cutting board safety. A 2023 study published in Environmental Science & Technology found that chopping on polyethylene and polypropylene boards releases substantial amounts of microplastics — between 14 and 71 million particles annually per person, with mass releases ranging from 7.4 to 50.7 grams.

Another concerning study from 2022 demonstrated that cutting meat on plastic boards releases microplastics that adhere directly to chicken, fish, and beef surfaces. Most alarming, research published in the New England Journal of Medicine in 2024 linked micro and nanoplastics found in arterial plaque to significantly higher cardiovascular event risks and mortality rates over a three-year period.

- Deep scratches and residue on plastic cutting boards can shed microplastics directly onto food

Advantages and Risks of Plastic Cutting Boards

The Advantages

Plastic cutting boards have earned their place in millions of kitchens for good reasons. Their lightweight construction makes them easy to maneuver, especially helpful when transferring chopped ingredients directly to pots or pans. The affordability factor cannot be overlooked either – you can purchase multiple plastic boards for the price of one quality wood board, making it practical to maintain separate boards for different food types.

Unlike wood boards, plastic doesn’t absorb water, which means they won’t warp, crack, or cup like wooden boards exposed to moisture. This water resistance also means they can withstand the high temperatures of dishwashers, making sanitization more convenient for busy home cooks. The dishwasher’s hot water cycle (140–160°F) effectively kills most bacteria when combined with proper detergent.

Most modern plastic cutting boards are made from HDPE (high-density polyethylene) or PP (polypropylene), both of which are BPA-free and certified for food contact by the FDA. These materials meet stringent safety standards for initial use and don’t leach harmful chemicals under normal kitchen conditions.

- Plastic cutting boards are lightweight, affordable, and dishwasher-safe — making them a practical choice for busy kitchens

The Risks and Drawbacks

Despite these advantages, plastic boards present several concerns that deserve serious consideration. The primary issue stems from their susceptibility to deep knife scarring. Unlike wood, which has some self-healing properties due to its fibrous nature, plastic develops permanent grooves with every cut. These grooves become hiding spots for bacteria, creating microscopic valleys where even thorough washing may not reach.

A Journal of Food Protection study from the University of Wisconsin–Madison found that deep grooves in plastic cutting boards trap food and moisture, making them harder to sanitize and more likely to harbor bacteria. The University of Maine Extension likewise warns that scratched boards can become contamination risks if not replaced promptly.

The microplastic issue represents a newer but equally concerning risk. Every knife cut shaves off tiny plastic particles. While the long-term health effects of microplastic consumption are still being studied, the cardiovascular research mentioned earlier suggests serious health risks. The particles are so small they’re invisible to the naked eye, meaning you could be consuming them without awareness.

- Each knife cut on a plastic board can release invisible microplastic particles into your food

Environmental considerations also weigh against plastic boards. Most plastic cutting boards end up in landfills after their relatively short lifespan, since the scarred and contaminated surface makes them unsuitable for recycling in most municipal programs. The production process relies on petroleum products and generates greenhouse gases, making plastic boards a less sustainable choice compared to renewable alternatives.

- Most plastic cutting boards end up in landfills, as their scarred and contaminated surfaces make recycling nearly impossible

Types of Plastic Boards & How They Differ

Understanding the differences between plastic board materials can help you make a more informed choice if you decide to use them.

HDPE (High-Density Polyethylene) represents the premium option in plastic cutting boards. This material offers superior durability and scratch resistance compared to other plastics. HDPE boards maintain their integrity longer under regular use, developing fewer deep grooves that harbor bacteria. Research indicates HDPE releases fewer microplastics than softer plastics due to its denser molecular structure. Professional kitchens often choose NSF-certified HDPE boards for their durability and compliance with commercial food safety standards.

- HDPE cutting boards are the premium plastic option, offering superior durability and scratch resistance

PP (Polypropylene) boards cost less than HDPE but come with trade-offs. While PP handles heat better — making it dishwasher-safe at higher temperatures — its softer composition means knives cut deeper grooves more quickly. This accelerated scarring leads to faster deterioration and increased microplastic release. A 2023 study found PP boards released approximately 15% more microplastic particles than HDPE boards under identical cutting conditions.

- Polypropylene cuts deeper under knives, releasing more microplastics than HDPE

Composite boards combine plastic resins with wood fiber or paper pulp, creating a hybrid material. These boards feel more substantial and knife-friendly than pure plastic, with better heat resistance and less warping. However, they still release microplastics, and their porous structure can absorb liquids over time, potentially harboring bacteria despite manufacturers’ antimicrobial additives. The mixed materials also make these boards impossible to recycle in standard facilities.

- The hybrid structure feels more solid than plastic yet still sheds microplastics over time

For practical purposes, HDPE serves best for regular kitchen use if you choose plastic, while PP works adequately for occasional use or as backup boards. Composite boards offer a middle ground but don’t fully solve the core issues with plastic cutting surfaces.

How to Use Plastic Cutting Boards Safely

If you currently use plastic cutting boards or plan to keep them for specific purposes, following proper safety protocols can minimize risks.

Reserve plastic boards for appropriate uses. Consider limiting plastic boards to short-term or outdoor applications where their lightweight and portable nature provides genuine advantages. They excel at picnics, barbecues, and camping trips where washing facilities might be limited and transport convenience matters most. For quick food prep tasks that don’t involve heavy chopping, plastic boards can serve adequately without generating significant microplastic contamination.

- Plastic boards are lightweight and portable, making them ideal for camping, BBQs, and picnics

Implement a color-coding system. The USDA recommends using separate cutting boards for different food types to prevent cross-contamination. If maintaining multiple plastic boards, designate specific colors for specific uses: red for raw meat, green for vegetables, yellow for poultry, and blue for seafood. This system, widely used in professional kitchens, significantly reduces foodborne illness risks.

- Color-coded cutting boards help prevent cross-contamination in both home and professional kitchens

Replace boards frequently. Given their shorter lifespan, plastic boards require regular replacement. For boards used daily, replacement every three to four months ensures you’re not using excessively scarred surfaces. Boards used less frequently might last six months to a year, but regular inspection remains crucial.

Recognize replacement indicators immediately. Discard any plastic board showing deep grooves that trap food particles, surface delamination or peeling, permanent discoloration despite cleaning, warping that prevents stable cutting, or persistent odors even after sanitization. These signs indicate the board has become a food safety hazard rather than a helpful tool.

- Easy way to spot when a plastic cutting board has reached the end of its safe lifespan

Practice proper cleaning and sanitization. After each use, wash plastic boards with hot, soapy water, scrubbing thoroughly to remove food particles from grooves. For additional sanitization, especially after cutting raw meat, apply a solution of one tablespoon of unscented bleach per gallon of water, letting it stand for several minutes before rinsing. Alternatively, run the board through a dishwasher cycle with heated drying for maximum bacterial elimination.

- A plastic cutting board being sanitized in the dishwasher for maximum food safety

Consider transitioning to safer alternatives. While proper use can make plastic boards relatively safe, exploring more sustainable and potentially safer materials makes sense for daily cooking. Wood, bamboo, and other alternatives offer unique benefits without the microplastic concerns inherent to synthetic materials.

Alternatives Worth Considering

| Material | Pros | Cons | Best For |

| Wood | Natural antimicrobial properties, self-healing surface, gentle on knives, sustainable when sourced responsibly | Requires regular oil maintenance, not dishwasher safe, higher initial cost | Serious home cooks seeking longevity |

| Bamboo | Harder than most woods, sustainable fast-growth source, naturally antimicrobial, lighter than hardwood | Can dull knives faster, requires oil maintenance, may split if not quality construction | Eco-conscious cooks prioritizing sustainability |

| Titanium | Completely non-porous, permanent antimicrobial surface, dishwasher safe, lifetime durability | Expensive, dulls knives quickly, loud cutting noise, can slip on counters | Professional settings requiring absolute sanitation |

- Comparison of alternative cutting board materials: durable wood, eco-friendly bamboo, and sanitary titanium

For most home kitchens, no single material is perfect for every task. Wood and bamboo work best for daily prep, offering durability and natural safety benefits. Titanium excels in hygiene but is costly and harder on knives. The smartest approach is to mix materials: use wood or bamboo for most cutting, and keep a dedicated board — whether plastic, wood, or titanium — for raw meat. An inexpensive plastic board is handy for outdoor cooking or travel.

Final Takeaways

The question of whether plastic cutting boards are safe has no one-size-fits-all answer. They can be safe with proper care, timely replacement, and limited use, but concerns over microplastic contamination make them less ideal for heavy, long-term use. No single material is perfect — wood and bamboo excel in durability and sustainability, titanium in hygiene, and plastic in portability and convenience. Choose based on how often you cook, the foods you prepare, and your willingness to maintain your boards. Whatever you choose, proper cleaning, inspection, and replacement are essential to keeping your cutting surface a safe and reliable kitchen tool.