Charcuterie boards add style to any kitchen, but their beauty often causes confusion about their purpose. Can you use a charcuterie board as a cutting board? The answer depends on its material, design, and hygiene standards – factors that determine whether it’s safe for everyday use or best kept for serving only.

Main Purpose of a Charcuterie Board

A charcuterie board serves as a decorative platform for displaying prepared foods. Its design prioritizes presentation over durability. These boards showcase arrangements of cured meats, aged cheeses, fresh fruits, roasted nuts, and artisan crackers. The surface typically features face-grain wood patterns, smooth finishes, and ornamental details such as handles or resin-filled edges that enhance their aesthetic value.

The construction focuses on visual impact rather than functional resilience. Manufacturers use thinner wood profiles and decorative treatments that make the boards lightweight and attractive. Many incorporate mixed materials – wood combined with marble inserts, metal accents, or colored resin – to create focal points for entertaining.

No, you generally should not use a charcuterie board as a cutting board. The distinction matters because these serving pieces lack the structural features needed to withstand knife work.

Common foods displayed on charcuterie boards include:

- Cured salamis and prosciutto

- Soft and hard cheeses (brie, aged cheddar, gouda)

- Fresh and dried fruits

- Assorted nuts and olives

- Crackers and bread slices

- Spreads and preserves

Each item arrives pre-cut and ready to serve. This usage pattern explains why the boards need only enough strength to support food weight, not knife force. The materials and build methods reflect this limited purpose, which makes them vulnerable when used for preparation tasks.

Material and Build

The main difference between charcuterie and cutting boards lies in how they’re built and what they’re made of. These details explain why each performs best in its intended role.

Charcuterie boards usually use face-grain wood, where the grain runs parallel to the surface. This creates smooth, beautiful patterns ideal for display. Common materials include acacia, olive wood, bamboo, marble, or slate. They’re often thin – about ½ to ¾ inch = and may feature resin fills that enhance appearance but weaken structure. These boards are made to look elegant, not to withstand heavy knife work.

Cutting boards, in contrast, use end-grain or edge-grain construction:

- End-grain boards stand wood fibers upright so knife blades slide between them, creating a self-healing surface that protects both board and knife.

- Edge-grain boards place the strips on their sides, balancing durability and knife-friendliness.

Preferred woods include maple, walnut, cherry, and teak. Professional-grade versions are 1.5–2 inches thick for stability and long life. Some use high-density polyethylene (HDPE) for added resistance to moisture and bacteria.

Under knife pressure, face-grain boards scar easily and absorb moisture through cuts, leading to warping and cracks. End-grain boards, however, compress and recover, extending both their lifespan and your knife’s sharpness.

| Feature | Charcuterie Board | Cutting Board |

|---|---|---|

| Grain Orientation | Face-grain | End/edge-grain |

| Typical Thickness | 0.5–0.75 inches | 1.5–2 inches |

| Primary Material | Acacia, olive, mixed media | Maple, walnut, teak, HDPE |

| Weight | Light to moderate | Substantial |

| Density | Variable, often lower | High, consistent |

| Surface Treatment | Decorative finishes, resin | Food-safe oil or bare wood |

These material weaknesses in charcuterie boards lead to visible and hidden damage when subjected to cutting tasks.

Risk of Damage

Cutting on a charcuterie board causes immediate and long-term damage. These boards are thin and face-grain, so they can’t handle repeated knife impact. Each cut compresses fibers, leaving visible grooves that worsen over time.

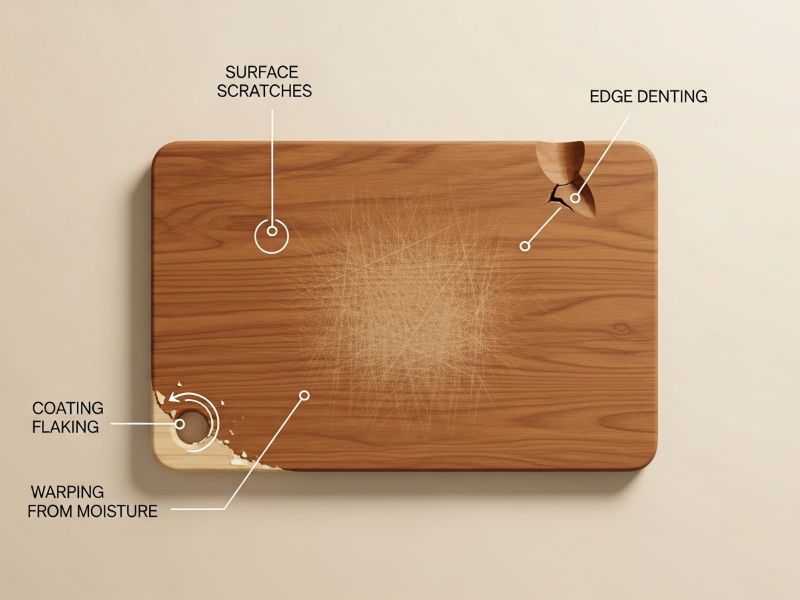

Damage manifests in several distinct ways:

- Surface scratches appear after minimal use. Face-grain wood shows every knife mark because blades sever continuous grain patterns rather than slipping between fibers.

- Edge denting occurs when cutting pressure reaches the board perimeter. Thin edges lack the mass to resist compression, leading to chips and splits.

- Coating flaking happens when decorative finishes or sealants crack under knife pressure. These protective layers separate from the wood base, creating rough patches and exposed material.

- Warping under moisture develops when knife grooves allow liquid penetration. Water enters the wood structure unevenly, causing some areas to expand while others remain stable. This differential movement creates permanent bends and curves.

As damage builds, appearance fades and structure weakens. Deep cuts trap food particles and moisture, turning the board into a bacterial risk rather than a safe serving surface.

Boards made from mixed materials – like wood with resin or marble inserts – suffer even more. Each material expands differently, so knife strikes create stress cracks and separations, especially along seams.

In short, using a charcuterie board for cutting ruins both its look and safety far faster than most people expect.

Hygiene Concerns

Once a charcuterie board is cut, its hygiene declines sharply. The porous surface absorbs liquids, and knife grooves trap food residue – creating perfect conditions for bacteria. Regular washing can’t reach these deep crevices.

How contamination happens:

- Food buildup: Meat proteins, cheese fat, and fruit sugars stick in cuts and cracks.

- Moisture retention: Damaged wood stays damp longer, allowing bacteria to multiply.

- Inaccessible cleaning: Decorative edges, grooves, and inlays trap debris that scrubbing can’t remove.

Scientific findings show that damaged, porous wood harbors harmful bacteria such as:

- E. coli – survives in moist residue, causes intestinal illness.

- Salmonella – lingers in wood grain, linked to food poisoning.

- Listeria monocytogenes – thrives in cracks; risky for pregnant and elderly people.

- Campylobacter – spreads from raw poultry contact.

Because charcuterie boards hold ready-to-eat foods, any contamination transfers directly to what you serve. Using the same board for both raw prep and serving creates unavoidable cross-contamination – even with thorough washing.

In short, the same design elements that make charcuterie boards attractive – thin wood, resin, carved handles – also make them unsanitary and unsafe for cutting or repeated food prep.

Stability Issues

Charcuterie boards lack the physical properties needed for safe cutting operations. Their lightweight construction and thin profile create instability during knife work. The reduced mass means less friction between board and counter surface. This mobility becomes dangerous when applying downward pressure with sharp blades.

Most boards measure under 1 inch thick and weigh only a few pounds, offering little friction against countertops. When you press or slice at an angle, they often shift or spin, reducing control and precision.

Unlike cutting boards, charcuterie boards lack non-slip features like rubber feet or textured undersides. Their polished bottoms glide across smooth surfaces.

Several design elements make charcuterie boards particularly unstable:

- Handles create uneven weight distribution and leave gaps under the board edges

- Decorative cutouts reduce surface contact with counters

- Raised feet or pedestals elevate boards, making them prone to tipping

- Irregular shapes with narrow sections provide inadequate support

This instability increases injury risk. A board that slips mid-cut can redirect the knife toward your hand or countertop. Professional kitchens avoid such hazards by using heavy, stable boards engineered for safety – something charcuterie boards were never designed to provide.

Difference from Cutting Boards

Cutting boards are engineered for performance and safety, while charcuterie boards prioritize appearance and presentation. Their structural and functional differences explain why they serve distinct purposes.

- Thickness & Stability: Cutting boards measure 1.5–2 inches thick, giving them the weight and stability needed for safe chopping. This mass also allows resurfacing – users can sand damaged layers and restore the board. In contrast, charcuterie boards are thin (0.5–0.75 inches) and light, designed for serving rather than impact resistance.

- Grain Orientation & Knife Impact: Charcuterie boards use face-grain wood, where fibers run parallel to the surface – beautiful but prone to scarring. Cutting boards use end-grain or edge-grain, where fibers stand vertically or sideways. This design creates self-healing surfaces and preserves knife sharpness far longer.

- Hygiene & Maintenance: Cutting boards often include juice grooves, non-slip bases, and tight-grain hardwoods like maple or walnut. These design choices limit bacterial growth and support deep cleaning and resurfacing. Charcuterie boards, with smooth finishes and resin fills, can’t withstand scrubbing or sanitizing without damage.

| Characteristic | Charcuterie Board | Cutting Board |

|---|---|---|

| Primary Purpose | Display and serving | Food preparation and cutting |

| Grain Orientation | Face-grain (decorative) | End/edge-grain (functional) |

| Hygiene Design | Basic smooth finish | Self-draining juice grooves, non-porous options |

| Durability | Moderate, decorative use | High, daily intensive use |

| Thickness | 0.5–0.75 inches | 1.5–2 inches |

| Maintenance | Gentle cleaning, preserve finish | Aggressive scrubbing, periodic resurfacing |

| Stability | Light, may shift | Heavy, anchored |

In short, charcuterie boards are for beauty, while cutting boards are built for work. Using one in place of the other risks damage – to both your board and your knives.

Final Recommendation

Use charcuterie boards only for serving – not cutting. This simple rule protects your investment, ensures hygiene, and preserves the visual appeal that makes these boards special.

Cutting on a charcuterie board quickly ruins its surface and decorative finish. These boards are designed for presentation, not impact. Once damaged, repairs remove the features that gave them value. In contrast, cutting boards are built to handle knife pressure, last longer, and cost less over time.

Proper tools also protect your knives. End-grain or edge-grain cutting boards extend blade life by absorbing impact rather than resisting it. Using the right board saves both time and sharpening costs.

From a food safety standpoint, keeping tools separate is essential. Designate cutting boards for raw and cooked foods, and reserve charcuterie boards for ready-to-eat items. This simple habit eliminates cross-contamination risks.

At Koppen, we recommend maintaining distinct boards for prep and presentation. Invest in a durable hardwood cutting board for daily cooking, and save your charcuterie board for special occasions when presentation matters most.