Mahogany cutting boards catch the eye with their rich, reddish-brown tones and elegant grain patterns. Many shoppers assume this prized hardwood offers the same kitchen reliability as maple or walnut. Yet food-safety experts and experienced woodworkers raise concerns about porosity, maintenance demands, and potential toxicity. This evaluation draws on material science, hygiene standards, and long-term kitchen use to help you decide whether mahogany belongs in your food-prep routine or should remain a decorative accent piece.

What Is Mahogany Wood?

Mahogany is a group of tropical hardwoods known for their rich color and smooth workability. Genuine mahogany (Swietenia) comes from Central and South America, while African mahogany (Khaya) is softer and Philippine mahogany (Shorea) is not true mahogany. All share a medium-to-low Janka hardness of 800–1,000 lbf, making them less durable than maple or walnut for cutting-board use.

The wood has an open-grain structure, allowing moisture and food particles to penetrate easily – an issue for hygiene. True mahogany is also CITES-regulated due to overharvesting, raising sustainability concerns. Although often marketed as a premium exotic option, mahogany’s strengths shine in furniture and boatbuilding, not in food-prep applications where hygiene and durability matter most.

Structural & Mechanical Properties

Mahogany’s open grain and moderate density make it more absorbent and less stable under kitchen conditions. With a density of 31–37 lb/ft³ (lighter than maple’s 44 lb/ft³), it offers less resistance to knife impacts and wears down faster. Moisture absorption also increases the risk of warping, staining, and odor retention.

| Property | Mahogany | Hard Maple | Black Walnut |

|---|---|---|---|

| Janka Hardness (lbf) | 800–1,000 | 1,450 | 1,010 |

| Density (lb/ft³) | 31–37 | 44 | 38 |

| Grain Structure | Open | Closed | Semi-closed |

| Moisture Absorption | High | Low | Moderate |

Although visually beautiful and deepening in color over time, mahogany’s porosity allows juices and oils to seep in, making stain and odor buildup difficult to avoid – even with regular oiling.

Is Mahogany Good for Cutting Boards?

The direct answer is: not ideal, though conditionally usable for light-duty tasks. Mahogany can serve as a decorative serving board or occasional prep surface, but it falls short as a primary cutting board for several critical reasons.

Why People Consider Mahogany for Cutting Boards

Several factors drive the interest in mahogany boards:

- Visual appeal: The deep red tone and straight grain add elegance to any kitchen.

- Perceived prestige: Mahogany’s reputation in high-end furniture creates an impression of luxury.

- Softer hardness: Lower Janka ratings promise gentler treatment of knife edges.

- Marketing claims: Some brands position mahogany as a premium, exotic alternative to common woods.

Online listings often highlight beauty while overlooking hygiene and performance drawbacks. Buyers drawn to its aesthetics may not realize that practicality is limited, and that mahogany’s performance under real kitchen use tells a different story.

Though conditionally usable for light-duty tasks, mahogany functions best as a decorative serving board or occasional prep surface, but it falls short as a primary cutting board for several key reasons:

- Softness vs. durability: With a Janka rating of 800-1,000 lbf, mahogany sits below the optimal range, easy on knives, but prone to dents and gouges that harbor bacteria.

- Porous grain: Its open structure readily absorbs liquids and odors, raising hygiene concerns and making cross-contamination more likely.

- Moisture sensitivity: The wood swells and shrinks with humidity changes; frequent washing can warp or crack it if not carefully dried and oiled.

- High upkeep: Regular oiling, prompt cleaning, and thorough drying are essential to prevent degradation.

| Criteria | Mahogany Performance |

|---|---|

| Knife-friendliness | Good (soft) |

| Bacteria resistance | Poor (porous) |

| Moisture stability | Fair (requires care) |

| Durability | Fair (scratches easily) |

| Maintenance | High (frequent oiling) |

Food-safety authorities and professional chefs generally recommend dense, closed-grain woods like maple for everyday food preparation. Mahogany remains a niche option where appearance outweighs function: appealing to the eye, but less so for practical, sanitary use.

Pros and Cons of Mahogany Cutting Boards

Weighing the benefits against the limitations clarifies where mahogany fits in your kitchen toolkit.

Advantages

Mahogany offers several appealing features that explain its continued presence in kitchenware catalogs:

- Attractive color and grain: The reddish-brown hue and straight, interlocking grain create a striking visual that complements natural-wood kitchen themes.

- Gentle on knives: Lower hardness reduces edge wear, prolonging the interval between knife sharpening sessions.

- Stable under controlled humidity: In climates with consistent indoor moisture levels, mahogany resists warping better than some denser hardwoods.

- Easy to refinish: Sanding out scratches and reapplying oil restores the surface without specialized equipment.

- Aesthetic warmth for serving: As a charcuterie or bread board, mahogany adds sophistication without the hygiene risks of heavy cutting.

These positives make mahogany suitable for display and light serving tasks. The wood’s beauty shines when food contact is minimal and presentation matters. Daily cutting performance, however, tells a different story.

Disadvantages

The drawbacks directly affect food safety and long-term usability:

- Porous nature harbors bacteria: Open grain traps moisture and food particles, creating pockets where pathogens survive standard washing. Studies indicate that porous cutting boards require more rigorous sanitation than dense options.

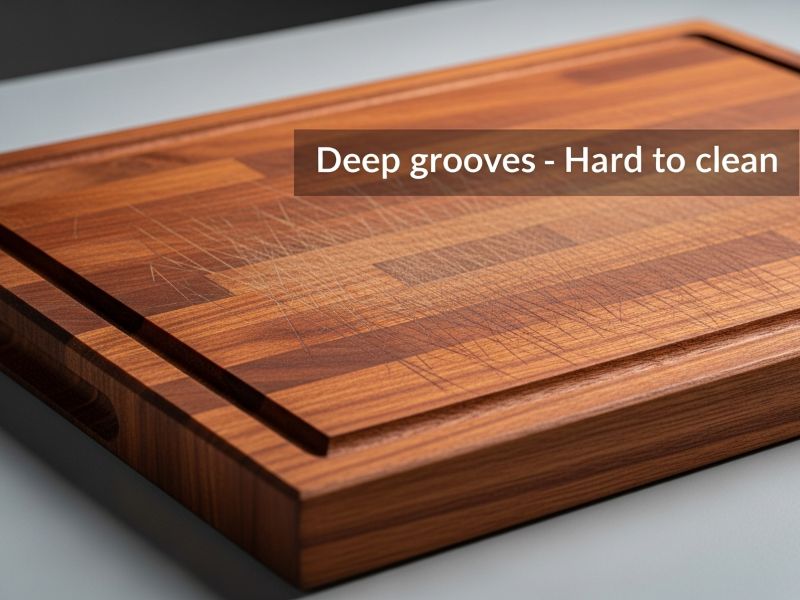

- Lower hardness leads to faster damage: Knife impacts leave deeper grooves, which accumulate debris and become harder to clean over time.

- Potential irritant oils: Some mahogany species contain natural compounds that cause skin irritation or respiratory sensitivity in sensitive individuals. While not common, the risk exists with prolonged contact.

- High maintenance burden: Effective sanitation requires frequent mineral-oil treatments, immediate post-use cleaning, and complete drying. Neglect accelerates bacterial buildup and structural degradation.

- Sustainability concerns: True mahogany faces overharvesting pressures, and illegal logging remains an issue. Responsible sourcing is difficult to verify without certifications.

These disadvantages directly compromise food safety, especially when preparing raw meat or handling acidic ingredients that penetrate the wood. The maintenance required to mitigate these issues exceeds what most home cooks want to manage.

Read more: Best Wooden Cutting Boards For Slicing, Chopping In 2025

Safety Concerns with Mahogany Cutting Boards

Food-contact safety extends beyond surface cleanliness to include wood chemistry and bacterial retention. Mahogany’s properties raise multiple red flags.

Limited approval for food surfaces: Regulatory bodies such as the USDA focus on woods with proven safety records for food prep. Mahogany rarely appears on recommended lists because its open grain and natural compounds have not undergone the same scrutiny as maple or walnut.

Possible natural toxins: Exotic tropical hardwoods can contain limonoids, alkaloids, or terpenes that deter insects and fungi in their native environments. While toxicity from brief food contact is unlikely, repeated exposure through cutting-board use introduces uncertainty. Sensitive individuals may experience allergic reactions or skin irritation.

Bacterial buildup in grain structure: Research from food-safety labs shows that open-grained woods retain bacteria longer than tight-grained species. Mahogany’s porous texture allows Salmonella, E. coli, and other pathogens to penetrate beyond the reach of surface scrubbing. Hot-water rinsing and soap help, but complete sanitation proves difficult.

High maintenance burden: Keeping a mahogany board safe requires more effort than denser alternatives. You must oil the board frequently to seal the grain, wash it immediately after use, and dry it thoroughly to prevent moisture retention. Miss these steps, and bacterial colonies establish themselves deep within the wood.

Professional chefs and food-safety authorities favor tight-grain woods like hard maple, which naturally resist bacterial penetration and require less intensive upkeep. The USDA and National Sanitation Foundation highlight maple’s track record in commercial kitchens, where hygiene standards are non-negotiable. Given these concerns, what woods offer better performance?

Better Alternatives to Mahogany Cutting Boards

If mahogany’s limitations outweigh its aesthetic appeal, several proven alternatives deliver superior safety, durability, and ease of maintenance.

| Wood Type | Janka Hardness (lbf) | Grain Structure | Hygiene Rating | Sustainability | Knife-Friendliness |

|---|---|---|---|---|---|

| Acacia | 1,170 | Closed to semi-closed | Very good | Excellent (sustainably grown, renewable) | Very good |

| Bamboo | 1,380 | Fibrous | Good | Excellent (fast-growing) | Fair (harder on knives) |

| Hard Maple | 1,450 | Closed | Excellent | Good (domestic) | Excellent |

| Black Walnut | 1,010 | Semi-closed | Very good | Good (domestic) | Very good |

| Teak | 1,070 | Closed, oily | Excellent | Fair (often imported) | Good |

Hard maple stands as the industry benchmark. Its tight grain and high density resist bacterial penetration, and the FDA recognizes maple as safe for food-contact applications. Commercial kitchens rely on maple butcher blocks for this reason. The wood’s hardness protects knife edges while standing up to heavy daily use. At Koppen, our maple cutting boards undergo rigorous quality checks to ensure consistent density and food-grade finishes.

Black walnut combines beauty with better hygiene than mahogany. Its semi-closed grain offers more resistance to moisture than mahogany’s open structure, and the wood’s natural tannins provide mild antimicrobial properties. Walnut’s rich chocolate tones appeal to design-conscious cooks who want function and aesthetics.

Teak and acacia bring natural oils that repel moisture, reducing maintenance demands. Teak’s closed grain and oil content create a self-sealing surface that resists bacteria and withstands humid environments. Acacia offers similar benefits at a lower price, though hardness varies by species. Both woods suit climates with high humidity, where other woods might warp.

Bamboo provides an eco-friendly option with rapid renewability. Its fibrous structure and high density resist bacteria, though the material’s hardness can dull knives faster than maple. Bamboo boards require glue lamination, so verify that manufacturers use food-safe adhesives.

Choosing the right wood depends on your priorities. For daily food prep, Maple delivers unmatched safety and durability. If aesthetics matter, walnut offers a practical compromise. Teak and acacia excel in demanding conditions, while bamboo satisfies sustainability-focused buyers. Mahogany remains best suited for decorative roles where cutting is minimal.

Read more: Best Wood for Cutting Boards: Which Wood is Right for You?

Conclusion

Mahogany cutting boards are appealing due to their rich color and smooth grain, but they pose hygiene issues due to their open structure and moderate hardness. While they can serve as decorative serving boards or for light prep tasks, they are not suitable for daily use with raw meat, acidic foods, or heavy chopping.

Consider this decision framework:

| Use Mahogany For | Avoid Mahogany For |

|---|---|

| Decorative serving boards | Daily food prep |

| Charcuterie and cheese displays | Raw meat cutting |

| Bread and pastry boards | High-moisture tasks |

| Occasional light chopping | Primary kitchen workhorse |

Hard maple and black walnut are safer, more durable, and easier to maintain. Maple’s closed grain is ideal for food safety, while walnut offers warmth without compromising hygiene. Both woods require less frequent oiling and handle intensive cleaning better than mahogany. In summary, prioritize food safety and maintenance over aesthetics. Reserve mahogany for decorative use and choose maple or walnut for your cutting board needs. This choice will benefit your knives, food safety, and overall kitchen efficiency.