Choosing the right cutting board goes beyond convenience—it directly impacts your family’s health. Contaminated boards are a major source of foodborne illness, making material selection critical. In this guide, we review the 5 safest cutting board materials, combining expert recommendations, scientific insights, and real-world testing to help you pick the healthiest option for your kitchen.

What’s Considered Safe for a Cutting Board

Evaluating cutting board safety comes down to four key pillars: hygiene, chemical safety, durability, and environmental sustainability:

- Hygiene & Microbial Resistance: The most critical factor. Safe boards prevent bacteria from seeping into the surface, resist moisture retention, and can be fully sanitized with standard cleaning methods. Non-porous materials and those with natural antimicrobial properties provide extra protection.

- Chemical & Toxin Safety: A safe board must remain chemically stable under everyday use. It should not leach harmful substances when exposed to acidic foods, cleaning agents, or temperature changes. Materials containing formaldehyde, heavy metals, or unstable plastics should be avoided.

- Durability & Knife Safety: Cutting boards must maintain a smooth surface without deep grooves that trap bacteria. They should withstand daily knife impact while being gentle enough to preserve blade sharpness. Boards that crack, chip, or splinter create contamination risks and safety hazards.

- Environmental Sustainability: Safe choices also consider long-term impact. Boards made from renewable, low-toxin, or recyclable materials reduce exposure to harmful chemicals while supporting environmental health.

Each factor contributes essential elements to overall cutting board safety. Hygiene prevents immediate health risks, chemical safety eliminates long-term exposure concerns, durability ensures consistent performance, and sustainability supports ongoing health and environmental protection. Materials excelling across all four categories provide the safest foundation for food preparation.

What Are the Safest Cutting Board Materials?

The safest cutting board materials excel in hygiene, durability, chemical stability, and sustainability. Backed by research on bacterial resistance, chemical safety, and real-world performance, these options merge traditional kitchen wisdom with modern food science. Each has been tested and recognized by food safety experts, offering a reliable, healthy, and eco-friendly foundation for everyday cooking.

Hardwood

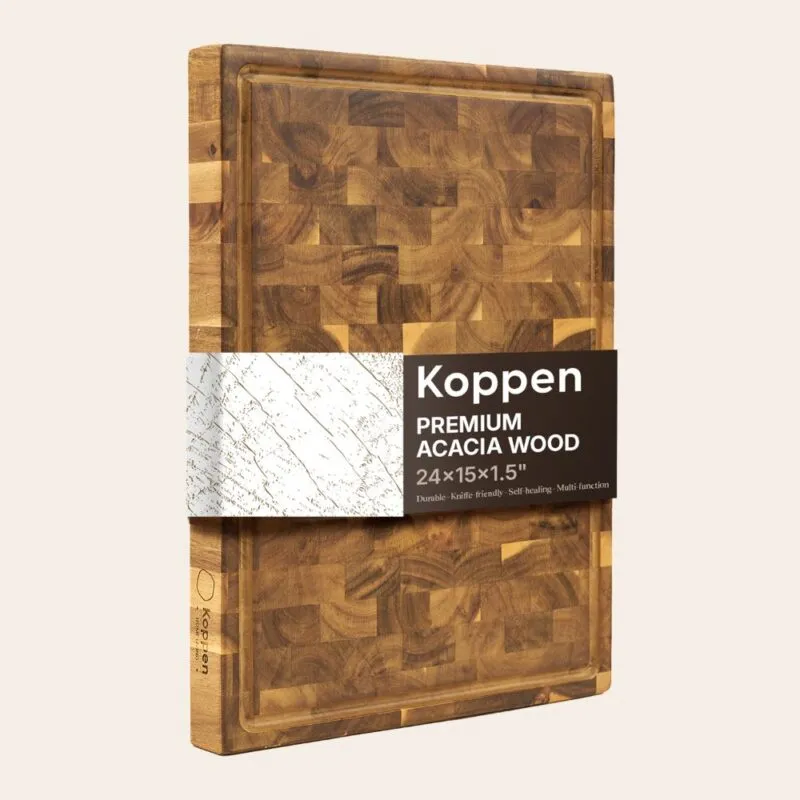

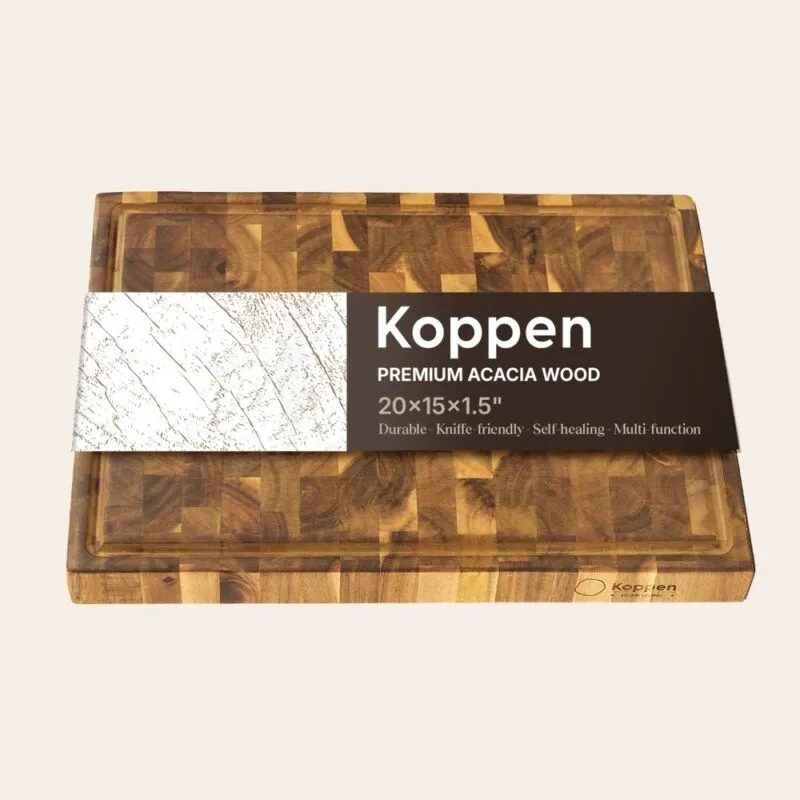

Premium hardwood cutting boards represent the gold standard for combining natural antimicrobial properties with exceptional durability and knife preservation. Dense hardwood species like maple, walnut, and cherry contain tannins and other compounds that naturally inhibit bacterial growth while providing self-healing characteristics unmatched by synthetic alternatives.

Construction Types:

- End-grain: Premium boards with vertical fibers; knife edges slip between fibers, preserving sharpness. Naturally “self-healing” and extremely durable, lasting decades with care.

- Edge-grain: More affordable, with horizontal fibers that remain stable and antimicrobial.

- Face-grain: Best for presentation or light-duty serving rather than heavy chopping.

Maintenance Requirements:

- Regular mineral oiling preserves moisture balance and prevents cracks.

- Proper drying after each use prevents water absorption that could reduce antimicrobial properties.

Why Safe: Dense hardwood fibers naturally limit moisture penetration and bacterial survival. Tight grain structures resist contamination, while tannins and natural compounds actively inhibit pathogens. Both end-grain and edge-grain versions maintain these safety characteristics when properly maintained, making hardwood one of the most consistently reliable and health-conscious choices.

Bamboo

Bamboo cutting boards combine environmental sustainability with practical kitchen performance, offering rapid renewable growth cycles that support eco-conscious cooking practices. Traditional bamboo construction provides naturally antimicrobial surfaces through silica content and dense fiber structure, though standard bamboo presents limitations in moisture resistance that affect long-term durability.

Technological Advancements:

- Koppen’s MoistureBlock Technology restructures bamboo fibers at the molecular level to resist moisture absorption and microbial growth.

- This treatment maintains bamboo’s natural composition while significantly improving water resistance properties.

Enhanced Performance Benefits:

- Increased water resistance prevents warping and cracking that compromise board integrity

- Enhanced hygiene through reduced bacterial penetration into fiber structure

- Extended lifespan through improved moisture control and structural stability

- Maintained eco-friendly profile without introducing toxic chemical treatments

Why Safe: Naturally renewable bamboo fibers already possess antimicrobial qualities. When enhanced with MoistureBlock technology, bamboo achieves superior moisture resistance, reducing warping, cracking, and bacterial penetration. This makes it both a sustainable and safe option for eco-conscious kitchens.

High-Density Polyethylene (HDPE) Plastic

Commercial kitchen standards worldwide recognize HDPE plastic as the benchmark for food safety in high-volume environments. The material’s non-porous structure prevents bacterial penetration while enabling complete sanitization through standard dishwasher cycles, making it ideal for raw meat preparation and cross-contamination prevention.

USDA food safety guidelines specifically recommend HDPE cutting boards for foodservice operations due to their consistent performance under demanding sanitation protocols. The material maintains structural integrity through repeated high-temperature wash cycles while showing no chemical degradation or leaching into food products.

Key Safety Characteristics:

- Complete non-porosity eliminates bacterial harboring in surface scratches

- Dishwasher compatibility enables high-temperature sanitization

- Chemical resistance prevents degradation from cleaning agents and acidic foods

- Affordable replacement cost supports regular rotation for optimal hygiene

Performance Considerations: HDPE boards require replacement when knife grooves deepen sufficiently to trap food particles and resist cleaning. Visual inspection easily identifies replacement timing through groove depth assessment and surface wear patterns.

Why Safe: Completely non-porous, USDA-approved, and dishwasher-compatible, HDPE cutting boards allow reliable bacterial elimination with proper cleaning. Their affordability encourages regular replacement, ensuring consistently safe food preparation surfaces.

Rubber

Professional Japanese culinary traditions have long recognized rubber cutting boards as superior tools for maintaining food safety while preserving knife edges. The material’s unique combination of density and resilience creates cutting surfaces that resist groove formation while providing gentle knife contact that extends blade life significantly.

Rubber’s molecular structure creates naturally sanitary conditions through several mechanisms. The dense composition prevents deep bacterial penetration while maintaining sufficient flexibility to avoid knife damage. Unlike rigid materials that develop permanent grooves, rubber surfaces compress and recover, minimizing bacterial harboring spaces.

Professional Applications: Commercial sushi preparation, fine dining kitchens, and culinary schools consistently choose rubber boards for their reliability in high-stakes food safety environments. The material’s performance under professional demands demonstrates its suitability for home applications requiring maximum hygiene assurance.

Maintenance Advantages:

- Dishwasher-safe construction enables complete sanitization

- Easy cleaning through standard protocols removes all food residue

- Long service life reduces replacement frequency and environmental impact

- Knife-friendly surface minimizes blade wear and maintenance costs

Why Safe: Rubber’s dense but resilient surface resists deep grooves, minimizing bacterial harbors. Combined with dishwasher safety and professional-grade performance, rubber boards offer superior hygiene while preserving knife edges.

Stainless Steel or Titanium

Metal cutting boards represent the ultimate in non-porous hygiene, offering completely impermeable surfaces that eliminate bacterial penetration concerns entirely. These materials provide uncompromising sanitation capabilities for applications requiring absolute cleanliness assurance.

Stainless Steel Performance: Food-grade stainless steel delivers exceptional durability combined with heat resistance and dishwasher compatibility. The material withstands aggressive sanitization methods including bleach solutions and high-temperature sterilization without degradation. Easy surface sanitization through standard cleaning protocols ensures complete bacterial elimination.

Titanium Advantages: Lightweight construction compared to steel reduces handling fatigue while maintaining superior corrosion resistance and chemical stability. Titanium’s non-toxic, food-safe properties provide chemically inert cutting surfaces that won’t react with acidic foods or cleaning agents. The material causes less knife damage than stainless steel while delivering comparable hygiene benefits.

Why Safe: Both materials provide completely non-porous, chemically stable surfaces that eliminate bacterial penetration. Titanium in particular combines hygiene excellence with lighter weight, superior corrosion resistance, and less knife wear than stainless steel—making it one of the safest premium cutting surfaces available.

Read more: What Are the Best Cutting Board Materials for Safety and Performance?

What Cutting Board Material Should You Choose?

Selecting the optimal cutting board material depends on your cooking habits, safety needs, and lifestyle priorities. Key factors include food types, preparation frequency, maintenance preferences, and household health considerations.

Food-Type Considerations: Raw meat requires non-porous options like HDPE or stainless steel for complete sanitization. Vegetables pair well with hardwood or bamboo for knife-friendly, naturally antimicrobial surfaces, while bread and delicate foods perform best on end-grain hardwood.

Lifestyle Matching: Eco-conscious cooks favor sustainable hardwood or bamboo. Serious home chefs benefit from end-grain hardwood durability. Budget households find value in HDPE’s safety and easy replacement, while low-maintenance users prefer stainless steel or dishwasher-safe plastics.

Household Health Needs: Families with children, elderly, or immunocompromised members should use non-porous boards – HDPE, stainless steel, or titanium—for maximum hygiene.

Cross-Contamination Prevention: A multi-board system works best, with different boards (or colors) for raw meat, produce, and bread to ensure safe separation.

Professional kitchens often combine materials for specific tasks, a strategy home cooks can adopt for both performance and safety.

Care & Maintenance to Keep Boards Safe

Proper maintenance turns any cutting board into a long-lasting, hygienic surface. Following food safety authority guidelines prevents bacterial contamination and ensures reliable performance.

USDA and CDC-Approved Cleaning: Wash with hot, soapy water after each use. For raw meat, a diluted bleach solution (1 tbsp per gallon of water) provides hospital-grade disinfection.

Material-Specific Protocols:

- Hardwood & Bamboo: Clean immediately, air-dry fully, and treat monthly with mineral oil.

- HDPE Plastic: Dishwasher-safe for high-temp sanitization.

- Rubber: Compatible with both dishwasher and hand-wash cleaning.

- Stainless Steel or Titanium: Withstands bleach and high-heat sterilization without damage.

Cross-Contamination Prevention: Use color-coded or dedicated boards for different foods. Separate storage and clear labeling minimize mix-ups.

Replacement Indicators: Retire boards showing deep grooves, lingering odors, cracks, warping, or instability. Regular inspection ensures safe conditions and prevents contamination.

Final Verdict: The Healthiest Cutting Boards in 2025

Comprehensive evaluation shows hardwood cutting boards as the best all-around option for most kitchens. End-grain maple or walnut provides natural antimicrobial properties, durability, and knife preservation that justify the investment, delivering decades of safe performance with proper care.

HDPE plastic boards excel for raw meat and maximum sanitization, with a non-porous structure, dishwasher safety, and affordable replacement costs.

Bamboo boards enhanced with moisture-blocking technology offer eco-conscious cooks a sustainable, safe alternative, overcoming traditional durability limits.

The safest strategy is using multiple boards for different food categories—meat, vegetables, and ready-to-eat items—to prevent cross-contamination.

Ultimately, the healthiest cutting board is determined not only by material selection but also by consistent maintenance. The safest cutting board combines appropriate material characteristics with diligent cleaning protocols and timely replacement when performance degrades. This holistic approach ensures your kitchen foundation supports rather than compromises the health and safety of every meal you prepare.

Read more: Best Wood for Cutting Boards